Electrical Page

| CONSTRUCTION |

|

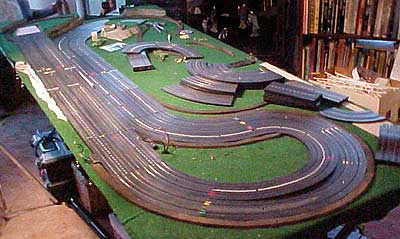

The FASCAR 500 track is built on a 32" hollowcore door. The track layout barely fits on the door, but I wanted spin aprons (curve borders) on all curves, so I screwed a furring strip (nominal 1x2" lumber, actual 3/4"x 1.5") to each of the long sides, making the overall layout size 35" x 79". I cut the ends of the furring strip at 45 degrees giving the table beveled corners, so people were less likely to snag their clothing as they walked around it, and especially as they squeezed into the drivers' area between the table and the couch.

|

The door was bought at a garage sale for $1.50, banged up and patched on one side. 32" doors are available at the second-hand building supplies store near me for a few dollars. New, they run about $25, but since nobody sees the surface, scratches, dents and holes don't matter much, so used is as good as new. If you don't want to bother with adding the extensions on the sides, get a 36" door, but they are harder to find than the 32" ones.

The tabletop (door) sat on two wooden "TV Tray" folding tables, and was surprisingly stable. Once the wiring was tested it was duct-taped to the underside of the table to keep the wires from hanging down and snagging.

The hills were slabs of styrofoam, cut or broken to shape, and with the exposed edges painted to resemble rock faces. Be sure to use plastic-compatible paint. They were stacked in layers. The long downhill straight was supported by a ramp of extruded styrofoam insulation, which has more rigidity than regular styrofoam beadboard.

The upward surfaces were topped with a green felt cloth just tacked to the table edges with a stapler or lightly glued to the hills with glue-stick. Model railroad lichen was used for bushes, scattered about and stuffed into any place where I wanted to hide something (a gap, electrical terminals, space under the ramp track). The trees were old plastic pine trees that snap together in layers (Aurora made a hard plastic version and AHM/Roco used to make flexible plastic ones). These don't shed fluffy foam or sawdust on the track, and can take a lot of punishment from players reaching to reslot cars.

Trees and people were held to the felt by tacky, water-soluble glue-stick. They pull off easily at takedown time, and pop off, instead of breaking, if hit by a car or a hand.

| TRACK |

The track was the old Aurora Model Motoring "pin and joiner" track. It was made for Aurora's Thunderjet and vibrator cars, and will handle competitor cars of the same era, such as Lionel, Tyco, Atlas, Marx, and Faller. Aurora's early AFX cars will run on it if the pin-end of the guide piece is used.

Since I was not able to find Model Motoring 6" radius 1/8 curves, I hand-modified three pieces of Tomy track to mate with the old Aurora. These worked, but the joints were rougher than I wanted occasionally causing cars to hang up. If anyone has a few Aurora MM or AFX 6"R 1/8 curves that you are willing to let go at a reasonable price, please contact me (not the common 6"R 1/4 curves, but the very short 1/8 curves, MM #1540 or AFX #2540). Broken joiner claws on the AFX track are all right with me.

|

Spin aprons were made from a model railroad product called HO cork roadbed. Each roadbed piece splits into two three-foot cork strips that bend around track curves to provide fishtailing space. This keeps cars on the outside lane from unfairly using the guardrails to power around the curves and saves wear on the car bodies and bumpers. I lightly sprayed the cork black, so it wouldn't look so much like, well, cork roadbed. To keep the nails from dimpling the cork near the track (as you see in the photo), I started nailing the cork near the outside edge. |

| WIRING and ELECTRICAL INFORMATION |

The Fascar 500 is wired for reliability and flexibility. Each lane has two feeder points to minimize the chance for dead spots and to reduce current drop on the distant parts of the course (three would be better). The controllers are Aurora's old dark blue Russkit-style 60-ohm pistolgrip units. These are better matched to the Thunderjet motors than the later 45-ohm golden-yellow controllers used with Aurora's AFX cars.

There is also a bypass controller (the DC steering-wheel style) that allows a pace car to circle any lane at a constant speed.

|

Click the wiring diagram at left to bring up a full-sized version. Wires connect only at dots. Wire-nuts make an insulated connection. The plan as drawn requires two of Aurora's separate clip-on terminal pieces. Allternate locations are shown if you wish to use standard 9" terminal tracks instead.

|

|

POWER

SUPPLIES and CONTROLS |

|

The powerpacks are held on the power board by self-adhesive magnetic strips stuck to the board. Any powerpack can easily be pulled off for repair or replacement. The screw-type terminal strip and the switched power-outlet-bar are held on the board by two-sided foam tape. A separate powerpack for each lane insures that no racer can cause a competitor to spin out by suddenly cutting power to his own car, thus causing an unexpected power boost to the other lanes |

|

|

Plugging all the packs into a permanently-mounted power-outlet bar minimizes cord clutter and lets the Course Marshall start races by simultaneously turning on power to all four lanes at the power strip switch. Get an outlet bar with a lighted switch, so you can tell when it's on - these are 40-year old powerpacks, so you want to make sure the power is turned off when you're not using them. Make sure all powerpacks have the same output voltage and are all DC packs. Aurora powerpacks came in a range of voltages, including 12, 18, 20, and 22-volt. The voltage is printed on the top, but it's not a bad idea to check them with a meter to make sure they are delivering the rated voltage. Do not use the Aurora AC early powerpacks intended for use with the vibrator cars - they will damage or burn out the DC motors on Thunderjet, AFX, Tyco and most other cars. If AC power reaches a DC motor even momentarily, the motor coils can be weakened, and sustained exposure can fry the motor. |

|

This photo shows the drivers' stations for the red and black lanes. Each station has a feed-thru style terminal strip screwed to the side of the table. Controller wires can clip or screw to these strips. Each station is marked with tape of the lane color and has a cup-hook to hang the controllers. The backs of the controllers themselves also sport a square of colored tape matching their lane. Barely visible in the shadow at right is the pace-car's constant-speed bypass controller which can clip to the terminals of any lane. Check the wiring diagram above to see which screws are used on the pace controller. The coffee-table (and clutter beneath it} were not a part of the racing table support system. They just happened to be under it. |

| FINIS |

|

All things come to an end. Lack of space means the equipment has to go back into storage. This time, though, it won't be another 15 years before it comes out again. A second race event is already in the planning stage. |

|

FASCAR - the Frivolous Antique Slotcar

racing association.